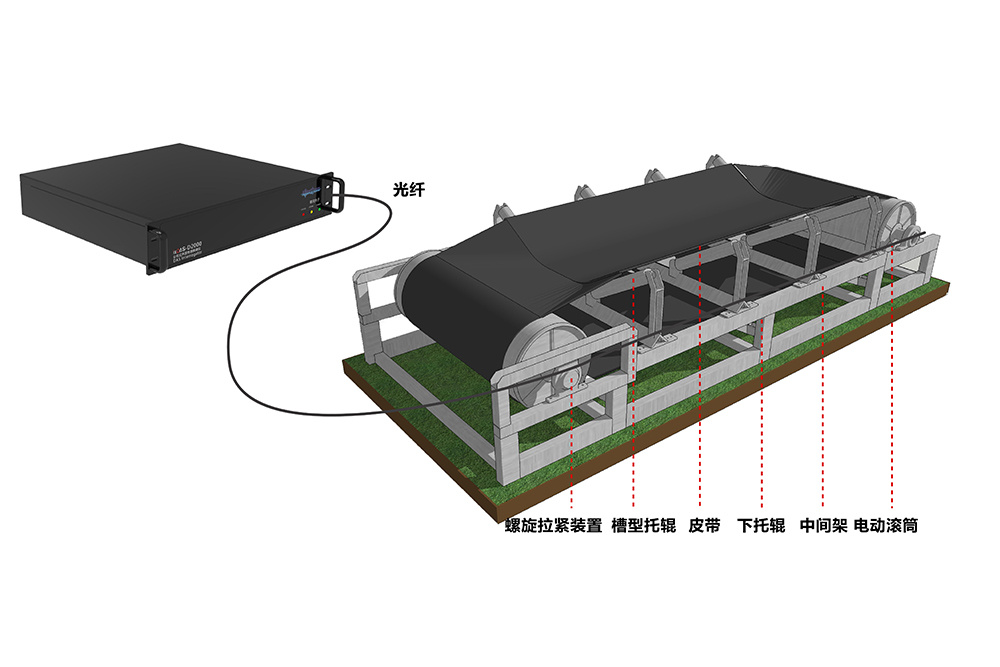

Belt Conveyor Fault Monitoring

Belt conveyors, widely used in industries such as mining, ports, and metallurgy, are typical large industrial equipment for material transportation. Distributed fiber optic sensing technology enables real-time fault monitoring of the entire length of belt conveyors, quickly locating and alarming for issues such as roller bearing eccentricity, axle deformation, cracks, bearing loosening or wear, ball drop, bracket loosening, and abnormal temperature. This timely detection and handling of abnormal conditions eliminate accident risks, reduce unexpected downtime and safety incidents, lower maintenance costs, and ensure safe operation.

Advantages:

1) Wide Monitoring Range: A single device can monitor belt conveyors extending several kilometers, with no spatial monitoring blind spots;

2) Accurate Fault Location: The precision of locating abnormal events is at the meter level, enhancing maintenance efficiency;

3) Real-Time Monitoring: Continuous 24-hour monitoring of belt conveyors, with no temporal monitoring blind slots;

4) Intelligent Fault Analysis: Intelligent acoustic recognition differentiates various types of faults, enabling fault warning;

5) Intrinsic Safety: Optical cables are durable in harsh environments, electrically insulated, and resistant to electromagnetic interference.

©Ningbo Lianhe Photon Technology Co., Ltd. All Rights Reserved

Powered by www.300.cn SEO Business License

WeChat official